2. Ventajas significativas: El recubrimiento en polvo tiene muchas ventajas sobresalientes, lo que demuestra su excelencia en el campo del recubrimiento industrial.

Buen desempeño ambiental: el material utilizado en el recubrimiento en polvo no contiene solventes orgánicos volátiles y no se generarán compuestos orgánicos volátiles (VOC) durante toda la operación de pulverización, lo que juega un papel positivo en la reducción de la contaminación ambiental y también puede proteger la salud de los operadores.

Alta tasa de utilización del recubrimiento: Los materiales utilizados en la pulverización de polvo son reciclables. Tras la primera pulverización, el espesor del recubrimiento puede alcanzar entre 60 y 150 micras, y la tasa de utilización total puede alcanzar entre el 90 % y el 98 %, lo que sin duda reducirá considerablemente el coste de producción.

Recubrimiento de primera calidad: El recubrimiento curado presenta una apariencia rica y uniforme, con una coloración suave y uniforme. Al no contener disolventes, previene eficazmente la formación de poros y burbujas de aire. Este recubrimiento ofrece una adhesión, resistencia a la corrosión y al desgaste excepcionales, así como propiedades de aislamiento eléctrico, lo que prolonga significativamente la vida útil del producto y mejora su atractivo visual.

Alta eficiencia de producción: basta con una sola pulverización para formar una capa relativamente gruesa, sin necesidad de pulverizaciones repetidas. Además, el equipo correspondiente puede operar en línea de montaje para realizar pulverizaciones continuas, lo que acorta considerablemente el ciclo de producción y mejora la eficiencia.

3. Los campos de aplicación de la máquina de recubrimiento en polvo electrostático son muy amplios y abarcan muchas industrias.

Maquinaria industrial y piezas metálicas: puede proporcionar un recubrimiento protector para carcasas metálicas y piezas de todo tipo de equipos mecánicos, mejorando su resistencia al desgaste y a la corrosión.

Componentes de infraestructura: Los componentes de infraestructura como soportes de metal, columnas, farolas y señales de tráfico pueden protegerse mejor de la erosión en entornos exteriores hostiles después del tratamiento de pulverización de polvo electrostático, lo que extiende su vida útil.

Productos relacionados con el transporte: piezas de automóviles, motores, herramientas eléctricas, herramientas neumáticas y otros productos relacionados con el transporte, con la ayuda de la tecnología de recubrimiento en polvo electrostático, pueden mejorar la calidad de la apariencia y el rendimiento protector de los productos.

Productos eléctricos y electrónicos: gabinete de interruptores, gabinete de instrumentos, carcasa de computadora y carcasa de equipo periférico y otros productos eléctricos y electrónicos, el uso de recubrimiento en polvo electrostático no solo puede lograr un buen efecto de aislamiento, sino que también mejora la apariencia de los productos.

En el sector de los electrodomésticos y muebles de acero, artículos domésticos de uso diario como ventiladores eléctricos, refrigeradores, máquinas de coser, lavadoras, planchas, carcasas de hervidores, ollas arroceras, calentadores de agua, aspiradoras, estufas eléctricas, bicicletas, paraguas y cerraduras, así como componentes arquitectónicos como ventanas de acero, puertas y ventanas de aluminio, travesaños, ascensores, portones de acero y puertas de uso militar, han adoptado ampliamente la tecnología de recubrimiento electrostático en polvo. Esta técnica mejora tanto la estética como la durabilidad de estos productos.

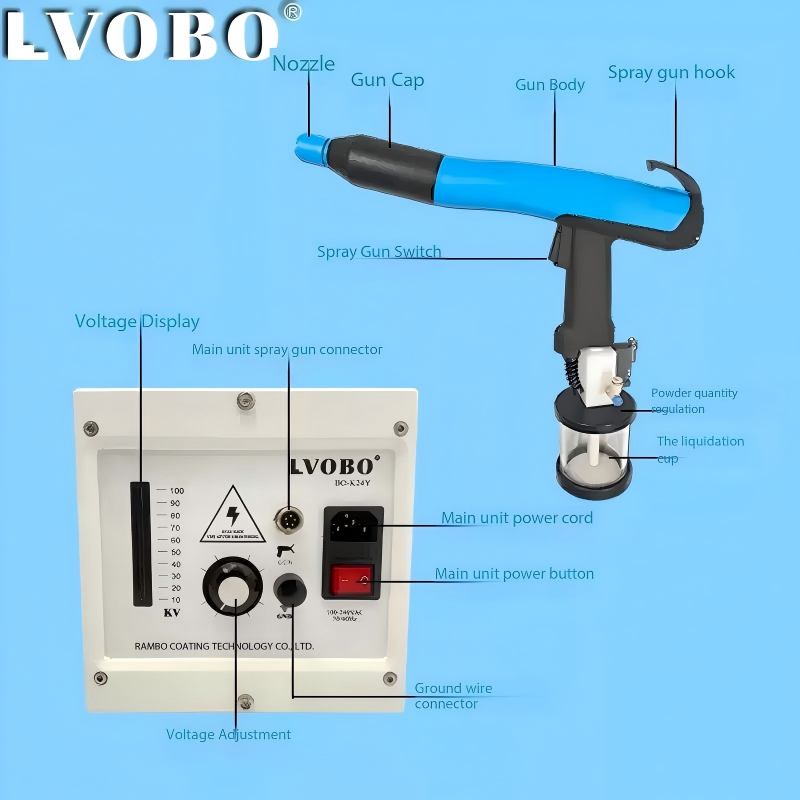

4.Puntos clave para comprar una pistola pulverizadora Hay varios puntos clave a tener en cuenta a la hora de comprar una pistola pulverizadora.

Selección de la pistola pulverizadora: la elección debe basarse en la escala de producción y las características del producto. Pistolas pulverizadoras manuales Son más adecuadas para producciones de lotes pequeños y múltiples, mientras que las pistolas pulverizadoras automáticas son más apropiadas para escenarios de fabricación repetitiva y de gran volumen.

Consideraciones sobre el sistema de suministro de polvo: Asegúrese de que el sistema de suministro de polvo seleccionado tenga buena fluidez y uniformidad, pueda suministrar polvo para la operación de pulverización de manera estable y evite fenómenos adversos como obstrucciones y precipitaciones.

Selección del generador electrostático: debe elegir el generador electrostático con voltaje de salida estable y un rendimiento confiable, solo de esta manera el efecto de adsorción del polvo puede alcanzar el estado ideal.

Preocupaciones sobre la limpieza y el mantenimiento de los equipos: priorice los equipos que sean fáciles de desmontar, limpiar y mantener, lo que puede reducir eficazmente los costos de mantenimiento posteriores.

Confirmación del alcance de aplicación: Verifique que el equipo sea compatible con el tipo de recubrimiento en polvo requerido (por ejemplo, resina epoxi, poliéster, etc.).

Garantía de seguridad: el equipo debe estar equipado con un dispositivo antiestático perfecto, protección contra sobrecargas y otro diseño de seguridad, a fin de garantizar la seguridad personal de los operadores.

En resumen, las máquinas de recubrimiento electrostático en polvo se han convertido en equipos indispensables en los procesos industriales modernos de recubrimiento, gracias a sus principios de funcionamiento únicos, numerosas ventajas y amplio campo de aplicación. Al cumplir estrictamente con estas consideraciones clave durante la adquisición y la operación, las empresas pueden aprovechar al máximo sus capacidades para generar mayor valor.

Español

Español English

English Español

Español Tiếng Việt

Tiếng Việt

IPv6 RED SOPORTADA

IPv6 RED SOPORTADA